Grace develops Extruders and Recycling Systems with Advanced Technology

Grace, one of the leading global companies developing solutions for the plastics industry, is confirmed for Interplast, where it presents its advanced parallel extruders for PVC granulation, in addition to its extrusion lines for PVC and PE pipes and complete systems recycling. Focusing on total process control, low maintenance and reduced energy consumption, the company stands out for providing high-efficiency equipment that meets the needs of modern industry.

One of Grace’s main highlights at Interplast 2024 will be the parallel extruder for PVC granulation. This equipment is designed for the manufacture of PVC compounds, providing total process control, low maintenance and a significant reduction in energy consumption. Grace extruders are known for their energy efficiency and production capacity, making them an ideal choice for manufacturers looking to increase productivity and reduce operating costs.

Grace extruders are equipped with advanced control systems that ensure precision and consistency in the production of PVC compounds. Designed to reduce the need for maintenance, the machines minimize downtime and maintenance costs. With cutting-edge technology, these extruders offer more efficient operation, reducing energy consumption and operating costs.

EXTRUDERS FOR PVC AND PE

In addition to extruders for PVC granulation, Grace presents its extrusion lines for PVC and PE, capable of producing tubes with diameters of up to 3000mm. These extruder lines are designed to offer high productivity and consistent quality, meeting the demands of various industrial and infrastructure applications.

Grace extrusion lines are capable of producing large volumes of tubes efficiently and consistently, including large diameter tubes for a variety of applications, from infrastructure to industrial projects. The extruders are equipped with advanced technology to ensure the uniformity and quality of the tubes produced.

COMPLETE RECYCLING SYSTEMS

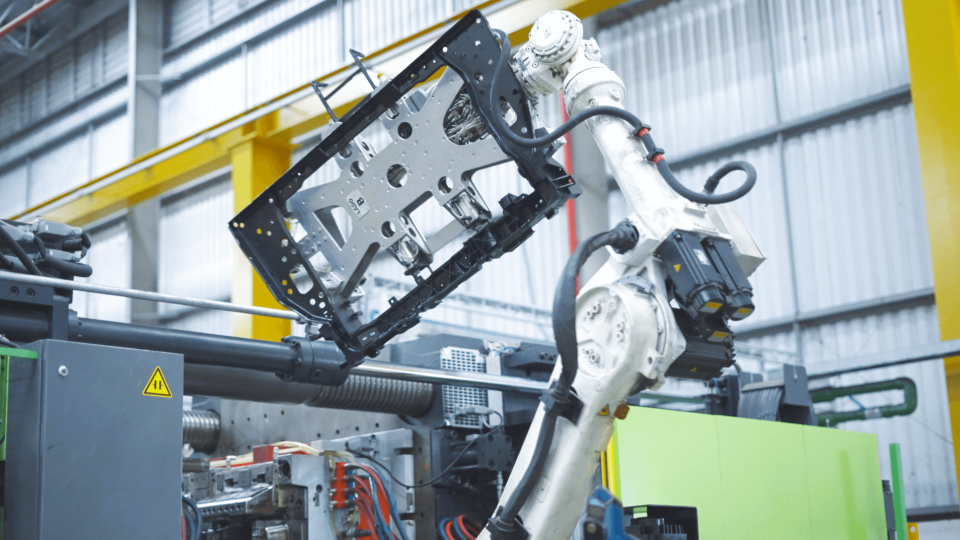

In addition to its expertise in extruders, Grace stands out for its complete recycling systems, which include washing, grinding and granulation lines. These systems are designed to provide efficient and sustainable recycling of plastics, contributing to the reduction of waste and the reuse of materials.

Advanced equipment cleans and prepares recyclable plastic materials and has efficient grinding systems that guarantee adequate preparation of plastics for granulation. In addition, extruders and granulation systems transform recycled plastics into high-quality granules, ready to be reused in the production of new products.

Grace is committed to sustainable practices, developing technologies that reduce energy consumption and promote efficient plastic recycling. The company constantly seeks to innovate and improve its processes to minimize environmental impact and contribute to the circular economy.

ABOUT GRACE

Grace is a company globally recognized for its innovative solutions for the plastics industry, specializing in the manufacture of extruders and recycling systems. Founded with a commitment to delivering advanced technology and operational efficiency, it offers high quality equipment that meets the needs of various industrial sectors. With a focus on sustainability and cost reduction, the company develops products that guarantee total process control, low maintenance and efficient energy consumption, consolidating itself as a reliable partner and leader in its segment.