Plastibras brings Innovative Solutions in Injection Molding, Vacuum Forming and Molds to Interplast

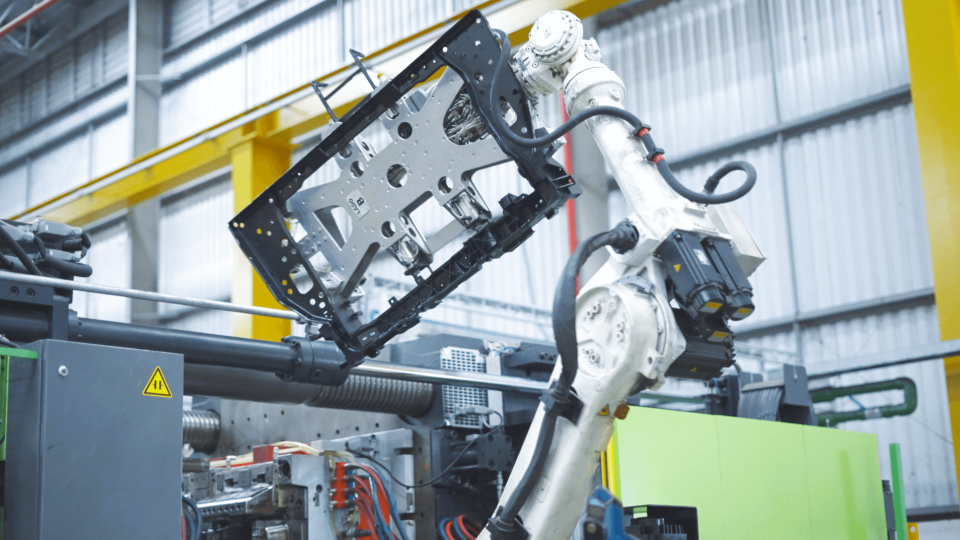

Consolidated in the plastics transformation market, Plastibras brings innovations in injection molding, vacuum forming and molds to Interplast. The company has injection molding machines with different closing force capabilities, which allows it to produce plastic parts with high technical standards. The injection molding machines operate quickly, precisely and safely, ensuring the development of diverse materials with excellence. Plastibras offers outsourcing services for any market segment, ranging from commodities to engineering plastics and PVC/CPVC.

The vacuum forming process at Plastibras is recognized for its technical precision and low cost in making molds and in molding the parts themselves. This method allows the production of thermoformed parts with exact dimensions and excellent finishing quality, whether high or low relief. The company stands out for its ability to deliver vacuum forming solutions that meet the specific requirements of customer projects.

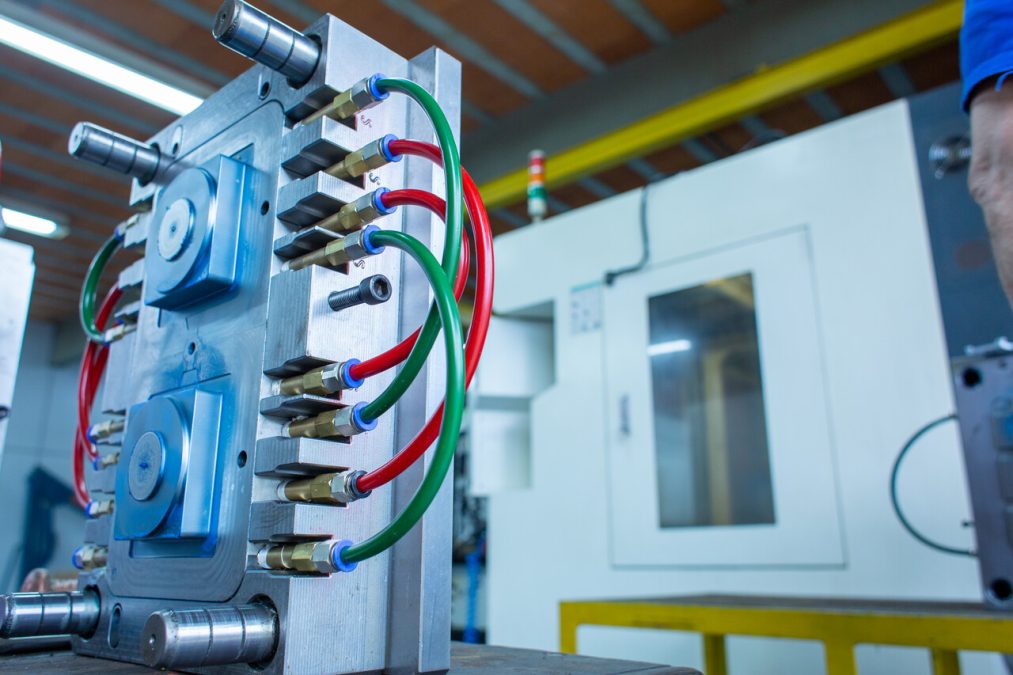

In addition to injection molding machines and vacuum forming, innovation is present in the tooling sector, equipped to perform quick maintenance and build molds for the most diverse market segments. The presence of an internal tooling department allows Plastibras to offer an agile and efficient service, guaranteeing the durability and quality of the molds produced. This structure makes it possible to respond quickly to customer needs, maintaining production continuity and efficiency.

Plastibras also has laser engraving and 3D printing machines. Laser engraving offers precision and quality in the finish, enabling customization and refined details in products. 3D printing allows rapid prototyping and the development of parts with complex geometry, providing greater flexibility and innovation in the production process.

REFERENCE IN THE SECTOR IN INJECTION MACHINES, VACUUM FORMING AND MOLDS

Plastibras is a consolidated company in the plastics transformation market, standing out for its use of high-tech machines in the production of injection molding, vacuum forming and mold manufacturing. The mission is to serve various market segments with products of superior quality, technical precision and cost-benefit, guaranteeing innovative and efficient solutions.

Plastibras offers outsourcing services for the production of plastic parts in any market segment, covering injection, vacuum forming and mold processes. The service allows companies to focus on their core activities, while Plastibras produces parts with high quality and precision. Outsourcing guarantees efficiency, cost reduction and access to advanced technologies without the need for heavy investment in own infrastructure.

The commitment to the customer is reflected in the constant training and training of the team and the continuous search for process improvements. The strategic location in Joinville-SC allows it to effectively serve companies from different segments and in different regions. Customer focus is one of the pillars that support our operations in the market, ensuring the satisfaction and loyalty of commercial partners.

ABOUT PLASTIBRAS

Plastibras stands out in the market for its advanced technology, personalized service and commitment to quality in injection technologies, vacuum forming and molds. Plastibras’ location in Joinville-SC is a key factor in the company’s success. The geographical position allows proximity to the main industrial centers in southern Brazil, facilitating logistics and quick and efficient customer service.