At Interplast 2026, Eletrothermo presents a robust and highly specialized portfolio of solutions for industrial heating, thermal control, and energy efficiency. The company demonstrates the breadth of its line of electric resistors, thermal equipment, and advanced infrared heating systems.

Eletrothermo’s portfolio includes electric resistors, thermal blankets, heating covers, ovens, furnaces, and complete systems for curing, drying, molding, polymerization, and thermoforming processes, being a national reference in the most diverse industrial segments.

For the plastics sector, Eletrothermo has technologies created specifically to meet the needs of machines such as thermoformers, extruders, injection molding machines, blow molding machines, and vacuum forming equipment. By bringing these solutions to Interplast 2026, the company connects with professionals, manufacturers, and integrators seeking greater productive efficiency, precise thermal control, and modern alternatives to reduce operating costs.

ELECTROTHERMO’S ELECTRIC RESISTORS ENSURE ENERGY EFFICIENCY AND HIGH PERFORMANCE

Among the highlights of the portfolio that will be presented at Interplast is the complete line of electric resistors, developed with a focus on efficiency, durability, and high thermal performance. The company offers infrared resistors in ceramic and quartz, collar resistors in mica, porcelain, cast aluminum, or bronze, cartridge resistors, tubular resistors, finned resistors, lamps for blow molding machines and PET, as well as ovens and furnaces designed for thermoforming and vacuum forming processes.

For the plastics sector, Eletrothermo develops specific solutions that guarantee greater thermal control and lower energy consumption. The line of ceramic and quartz resistors for thermoforming machines, for example, offers fast, efficient, and uniform heating, allowing for more stable production cycles and reducing losses due to temperature variation. Furthermore, the integrated thermal insulation of these components generates a significant reduction in energy consumption, a differentiating factor increasingly valued by industries seeking to optimize costs and meet sustainability requirements without sacrificing performance.

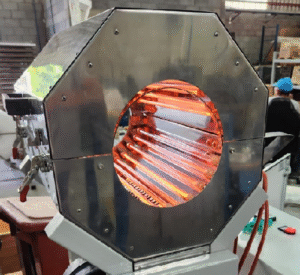

Another essential highlight is the set of infrared thermal covers, a technology developed for extruders and injection molding machines. These metal covers have thermal insulation and built-in infrared resistors, providing efficient and direct heating. The technology can offer up to 30% reduction in energy consumption, depending on the condition of the materials and the machine configuration. The lifespan of the set is also impressive: the metal structure has an indefinite lifespan, while the infrared resistors reach approximately 7,000 hours of operation, guaranteeing excellent cost-effectiveness.

Completing this line are the thermal insulation blankets for barrels and flat dies of extruders and injection molding machines. Produced with high-performance ceramic fiber, these blankets surround the barrel and prevent heat dispersion into the environment, preserving thermal energy at the critical point of the process. Depending on the application, the reduction in consumption can vary between 15% and 30%, making this technology an efficient and accessible strategy for industries seeking to improve their energy performance.

ABOUT ELETROTHERMO

Founded in 1988, Eletrothermo is a national leader in the development of electric resistors and complete industrial heating solutions. With over 37 years of experience, the company continuously invests in technology, research and innovation, offering high-performance equipment and systems for curing, molding, polymerization, drying, sintering and heat treatment processes.

Its portfolio includes electric resistors in various infrared emissivity ranges, thermal blankets, heating covers, ovens, industrial furnaces and custom-designed equipment. Serving industries such as plastics, packaging, paper and pulp, textiles, petrochemicals, finishing, decoration, glass and other segments, Eletrothermo stands out for its credibility, cutting-edge technology and commitment to transforming specific needs into precise industrial heating solutions.