At Interplast, Sulbras presents its solutions for high-performance plastic injection molding and molds for industries in the plastics segment. The company operates in an integrated manner with the development and manufacture of highly complex molds, the production of injected technical parts, and the delivery of ready-to-use plastic sub-assemblies for integration into clients’ production lines.

By integrating different stages of the production process into a single structure, Sulbras offers greater control, predictability, and safety to industrial projects, reducing risks and enhancing product performance. The complete solution in plastic components is designed for technical and industrial applications that require a high level of precision and reliability.

The integration between engineering, in-house tooling, and serial production allows for the optimization of each stage of the project, from product conception to large-scale manufacturing. This operating model enables significant efficiency gains, cost reduction throughout the product lifecycle, and greater agility in meeting market demands. “Our focus is on generating real value for customers, with high performance, reliability, and competitiveness throughout the entire project cycle,” says Sabrina Mezavilla, marketing analyst at Sulbras.

Sulbras operates predominantly in the B2B market, serving large national and multinational industries with a strong presence in strategic sectors such as automotive, white goods, agribusiness, industrial equipment, electronics, and durable consumer goods.

HIGH-PERFORMANCE PLASTIC INJECTION MOLDING THROUGH SULBRAS’ COMPETITIVE ADVANTAGE

Plastic injection molding is one of the pillars of Sulbras’ operations and represents a central element of its innovation and industrial efficiency strategy. By mastering all stages of the project cycle, the company is able to optimize solutions from conception, ensuring greater integration between design, engineering, and production. This complete mastery allows for cost reduction, improved technical performance of parts, and greater reliability in mass production.

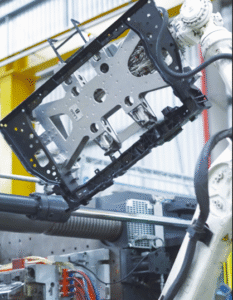

The manufacture of highly complex molds is another relevant differentiator. Sulbras continuously invests in technology, engineering, and processes to develop molds capable of meeting the highest standards of quality and precision. This expertise allows the company to offer advanced solutions for demanding technical applications, where dimensional tolerances, mechanical strength, and functional performance are critical factors.

The integration between molds, injection processes, and serial production results in greater predictability of results. For customers, this translates into reduced risks, greater production stability, and better cost control. By acting as a single partner throughout the project cycle, Sulbras simplifies process management and increases the operational efficiency of the industries it serves.

Another strategic aspect of Sulbras’ performance is its ability to develop ready-to-use plastic subassemblies for integration into customers’ production lines. This approach adds value to the product, reduces assembly steps, and contributes to the optimization of industrial processes.

Sustainability is a core principle of Sulbras’ engineering and processes. The company adopts continuous practices of production optimization, waste reduction, and efficient use of raw materials and energy. Furthermore, it develops solutions that allow for the reduction of part weight without compromising technical and functional performance, contributing to the reduction of environmental impact and the efficiency of products.

ABOUT SULBRAS

Sulbras is a 100% Brazilian company, founded in 1984, specializing in the development of injection molds and the production of technical plastic parts and sub-assemblies. With several industrial units in Brazil, the company serves major players in the B2B market, supported by a strong culture of engineering, innovation, quality, and long-term relationships with its clients.

Throughout its history, Sulbras has established itself as a strategic partner for industries in different segments, offering complete solutions in plastic components, molds, and injection processes. Its integrated operating model allows it to deliver projects with a high level of precision, reliability, and competitiveness, contributing to the development of Brazilian industry and the technological evolution of the plastics sector.