ARBURG Hybrid Injection has High Performance and Energy Efficiency

ARBURG, a renowned German family company and world leader in plastic processing technology, will be present at Interplast with its innovative ARBURG ALLROUNDER 570 H 1800 – 800 Packaging hybrid injection molding machine. This robust machine, with 180 tons of closing force, is configured to produce tubs of ice cream, promoting extremely high productivity and quality.

ARBURG is at the forefront of the plastics industry, offering cutting-edge packaging technology. Its hybrid injection molding machine guarantees high performance and productivity, as well as lower production costs. Committed to sustainability, the company developed the ALLROUNDER 570 H 1800 – 800 Packaging hybrid injection molding machine aiming for maximum energy efficiency with a reduction of up to 30% in energy consumption. This not only contributes to the environment, but also provides significant savings to customers.

The hybrid injection molding machine offers guaranteed high productivity, combined with exceptional precision, resulting in superior quality products. In addition to providing high-quality products and technology, ARBURG offers excellent customer support worldwide. With an extensive international sales and service network, customers can count on local support wherever they are. WIR SIND DA.

HYBRID INJECTION MACHINE AND CUSTOMIZABLE TECHNOLOGIES FOR INDUSTRY

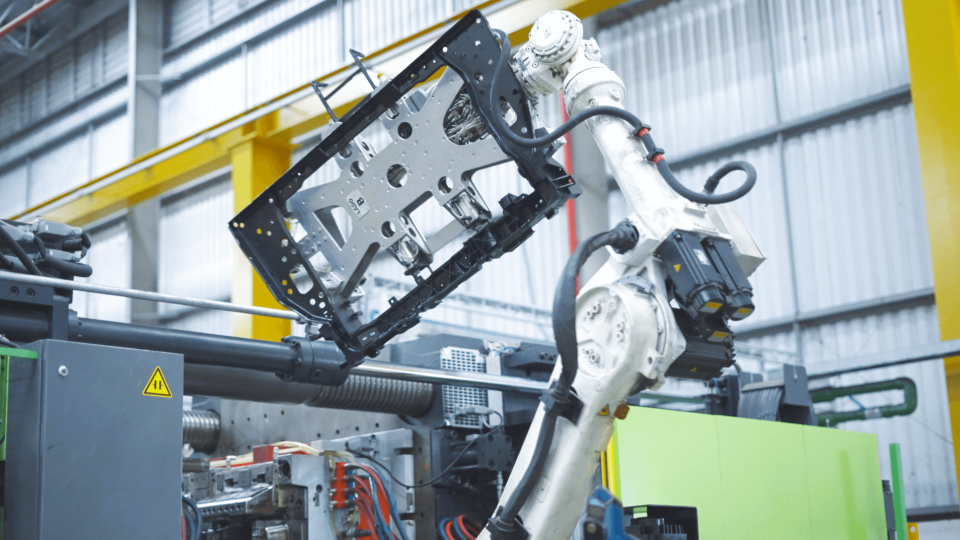

With a comprehensive portfolio that includes the Allrounder hybrid injection molding machine, robotic systems and complete customized solutions, ARBURG serves diverse industries such as automotive, packaging, electronics, medical technology and white goods. Its commitment to energy efficiency, digitalization and sustainability is evidenced by the “arburgXworld” program and the “arburgGREENworld” program, which outline its strategies and activities in these aspects.

In addition to the hybrid line highlighted at the fair, ARBURG is a manufacturer of hydraulic and electrical, horizontal and vertical injection molding machines, which offer solutions in special processes that require precision, repeatability and high quality, such as: silicone processing (LSR), multicomponents, with inserts, ceramic (CIM) or metallic (MIM) powders, microinjection, light structural parts, clean room, as well as complete turnkey solutions with automation and robotic systems. Everything integrated through its single GESTICA / SELOGICA command, which in combination with the ALS System, allows remote production control and monitoring.

ABOUT ARBURG

ARBURG is a renowned German family company and a world leader in plastic processing technology. With a history spanning almost seven decades, it has been a pioneer in the plastics industry, offering innovative, high-quality solutions for a variety of sectors, including the hybrid injection molding machine exhibited at Interplast.

Since 1956, ARBURG has been recognized for its excellence in manufacturing injection molding machines, including the hybrid injection Allrounder line, which covers a wide range of closing forces, covering everything from small parts to large volume products. In addition, the company also develops the freeformer, an industrial additive manufacturing technology, and robotic systems for process automation.