Company innovates with guided tours and promises to enrich the experience of visitors interested in plastic resins

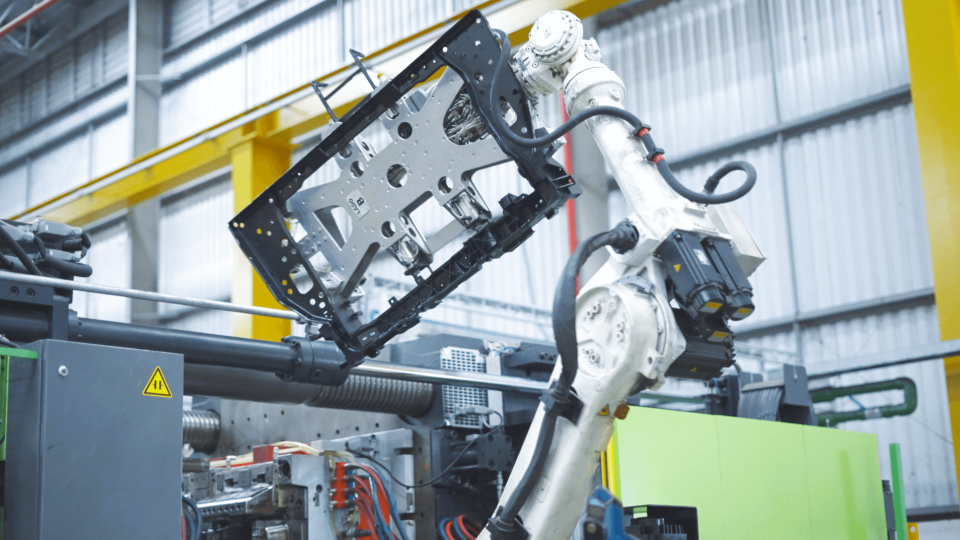

Braskem, the largest producer of thermoplastic resins in the Americas, is participating in this year’s Interplast with the launch of resins made from recycled materials, an exclusive lecture and a new feature: technical tours guided by the company’s application engineers. Visits will take place twice a day, throughout the event, and will offer enriching conversations about processes, innovations, industry trends and strategies that minimize the generation of plastic waste and promote reuse of materials.

The technical tours will take visitors to the stands of Braskem partners and distributors to learn about the company’s resins present in the products. Participants will receive detailed information on materials, sustainable processes and will have insights into the evolution of the industry and what to expect in 2025. Braskem is fully committed to contributing to the value chain to strengthen the circular economy. Therefore, the tours will address the topic and offer a unique opportunity for visitors to interact with professionals in the sector, exchange experiences and establish connections.

Braskem will also have three main highlights at the fair in terms of product: the CG800NAQ, DPR 010AW and DRL 007A resins. The CG800NAQ product is a copolymer polypropylene resin developed especially for frozen food packaging, which offers an excellent balance of processability and impact resistance at low temperatures. DPR 010AW and DRL 007A resins help reduce environmental impact, as they are biodegradable and recyclable.

DPR 010AW resin is an example. Derived from polypropylene and obtained from post-consumer packaging, it is made from 100% recycled material and not only meets growing demands for sustainability, but also offers excellent processability, with a flow rate of around 50 g/10 min. Another highlight is the DRL 007A resin, which also features post-consumer recycled material in its composition, being specially developed for use in flexible packaging.

“In technical terms, the Wenew DRP 010AW and DRL 007A resins stand out for their exclusive composition of recycled material, which does not compromise the quality or performance of the products. Such an approach not only reinforces Braskem’s position as a leader in sustainable innovation, but opens up new market opportunities”, says Fabio Agnelli, Application Engineering manager at Braskem.

EXCLUSIVE LECTURE AND TECHNICAL TOURS

The event held in the southern region of the country will also feature the CINTEC Plastics 2024 Congress in the program. In addition to the technical tours, Braskem will be present with an exclusive lecture, on August 15th, and the theme will be the sustainability journey for single-material packaging. “We are excited about this year’s Interplast. We believe it will be an incredible opportunity for us to showcase the new things we have developed and promote a strong exchange of experiences with visitors”, says Francisco Ruiz, the company’s application engineer.

ABOUT BRASKEM

Oriented towards people and sustainability, Braskem is committed to contributing to the value chain to strengthen the Circular Economy. The petrochemical company’s 9,000 Members dedicate themselves daily to improving people’s lives through sustainable chemical and plastic solutions. Braskem has innovative DNA and a complete portfolio of plastic resins and chemical products for various segments, such as food packaging, civil construction, industrial, automotive, agribusiness, health and hygiene, among others. With 40 industrial units in Brazil, USA, Mexico and Germany, the company exports its products to Customers in more than 71 countries.