Casafer highlights Technological Solutions to Increase Productivity in the Mold Industry

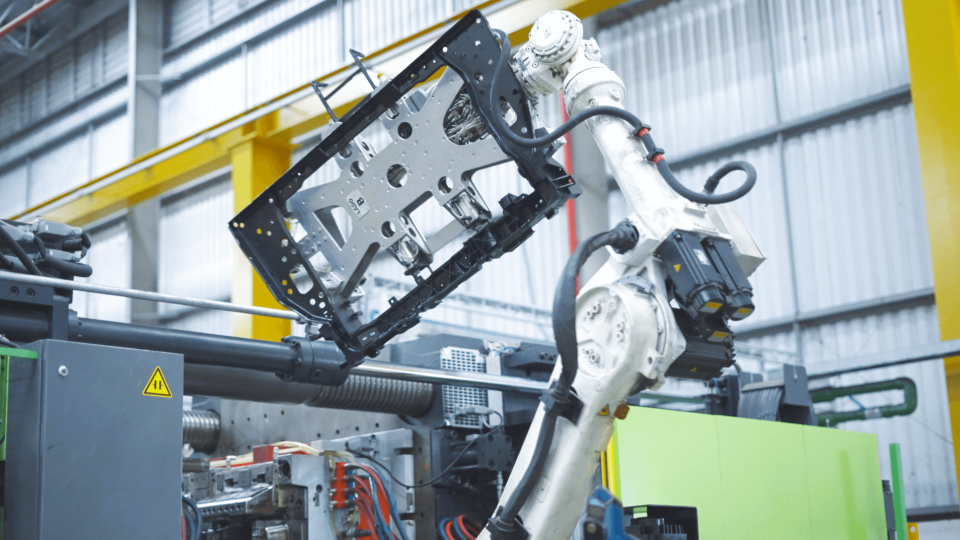

A reference in providing technological solutions designed to boost productivity in the plastic and metal parts transformation sector and for manufacturers of large-scale production tooling, Casafer exhibits its technological solutions at Interplast. With a wide range of standardized components and mechanisms, the company offers ideal options for the manufacture and maintenance of molds and stamps, aiming to optimize processes and guarantee high quality results.

At Interplast, it launches innovative solutions such as Coolingcare mold cleaning equipment, AESUB scanning sprays and Flosense refrigeration circuit monitoring systems, and will also present advanced technologies such as its Conformal Cooling solutions made with 3D metal printing, Systems Witosa injection systems and solutions for quick mold changes. Innovations are designed to maximize operational efficiency and improve product quality.

With the launch of advanced solutions for the mold industry such as Coolingcare and Conformal Cooling, Casafer offers state-of-the-art refrigeration technologies that use additive manufacturing to optimize mold cooling efficiency. This not only improves product quality, but also increases productivity and reduces cycle times.

MOLD AND STAMP INDUSTRY – SUSTAINABLE SOLUTIONS

The injection systems equipped with Monolith and EnergyBlocker technologies from the German manufacturer Witosa, presented by Casafer, provide significant reductions in energy consumption, reaching up to 52%. This not only contributes to the energy efficiency of the operation, but also to the reduction of operational costs in the mold and stamping industries.

In addition, Casafer offers a wide range of solutions for quick mold changes, cleaning of molds and cooling circuits, cooling circuit monitoring systems, separation of the injection channel from parts and a complete line of mold components. This ensures that customers have all the necessary tools to optimize their mold production and maintenance processes.

ABOUT CASAFER

Casafer is a leading company in providing technological solutions designed to optimize productivity in the plastic and metal parts processing sector, as well as for large-scale production tooling manufacturers. With a wide range of standardized components and mechanisms, it offers ideal options for the manufacture and maintenance of molds and stamps, aiming to improve industrial processes and guarantee high quality results.