SINO-TECH presents Injection and Blow Molding Solutions

At this year’s Interplast, SINO-TECH brings vast experience and expertise in providing quality solutions with excellent cost-benefit in injection and blow molds for plastic processing industries. As a Chinese diemaker with Brazilian characteristics, it has been committed to offering the best molds to Brazil since 2012.

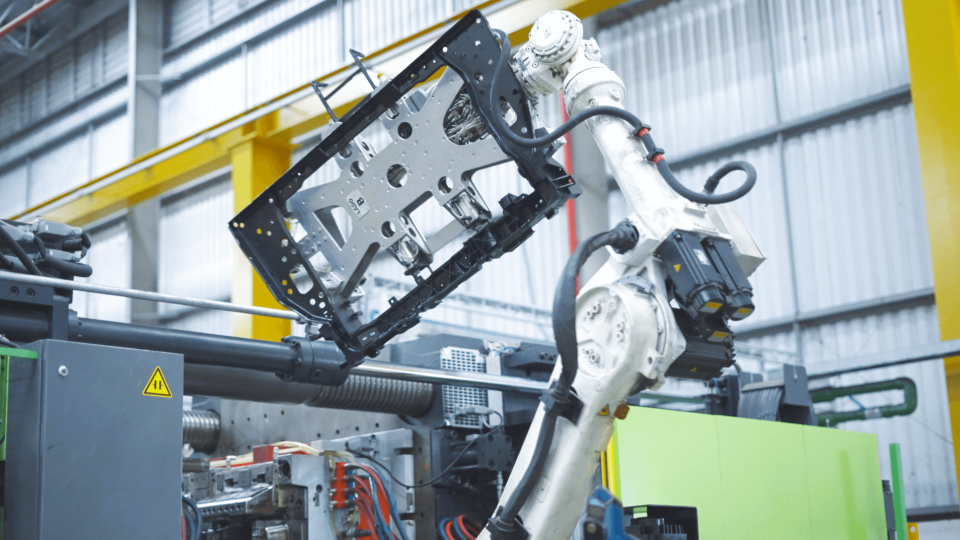

From small molds up to 15 tons, SINO-TECH specializes in developing injection and blow molds for a wide range of industrial applications. The products are recognized for the quality of the materials used, in addition to the excellent cost-benefit they offer to customers. The company is committed to providing exceptional customer service, always prioritizing the needs and satisfaction of business partners.

In its presence in the national market, it has already developed more than 1500 injection and blow molds for more than 35 companies, in addition to several other countries, including China, Morocco, Russia, Germany and India.

INJECTION AND BLOW MOLDING SOLUTIONS WITH SOLID PARTNERSHIPS

SINO-TECH is committed to building solid and lasting relationships with customers. The approach is to always put the client’s needs first, working collaboratively and transparently to find the best solutions. We are committed to solidifying the business-to-business partnership, ensuring customers receive not only high-quality products, but also exceptional service at every stage of the injection and blow molding process.

At Interplast, some of the products already developed by Interplast will be exhibited and the team will be available to serve customers and prospect new business opportunities. For the company, the fair is an excellent opportunity to network between customers and suppliers, contributing experience and commitment to quality in project development.

ABOUT SINO-TECH

Located in Huangyan City, famous for “China Mold Town”, SINO-TECH specializes in designing and manufacturing automotive molds, household appliance molds, utility molds, compression molds and parts. The company is equipped with about 20 sets of advanced mold processing machines and first-class CAD/CAE/CAM systems, and the seamless integration of hardware and software leads to a powerful core force in mold design and development. Furthermore, it has a technical team with rich experience and professional knowledge.

SINO-TECH adopted an ERP system and all these efforts, although recognized by customers, brought significant improvements to product quality and service. In the automotive industry, it has clients such as FAW, FAW-Volkswagen, Shanghai VW, Shanghai GM, Beijing Benz, Ford, Suzuki, TOYOTA, General Motors, BMW and Audi. At the same time, it expanded the business into molds for household appliances and air conditioners from the Hisense and LG brands.