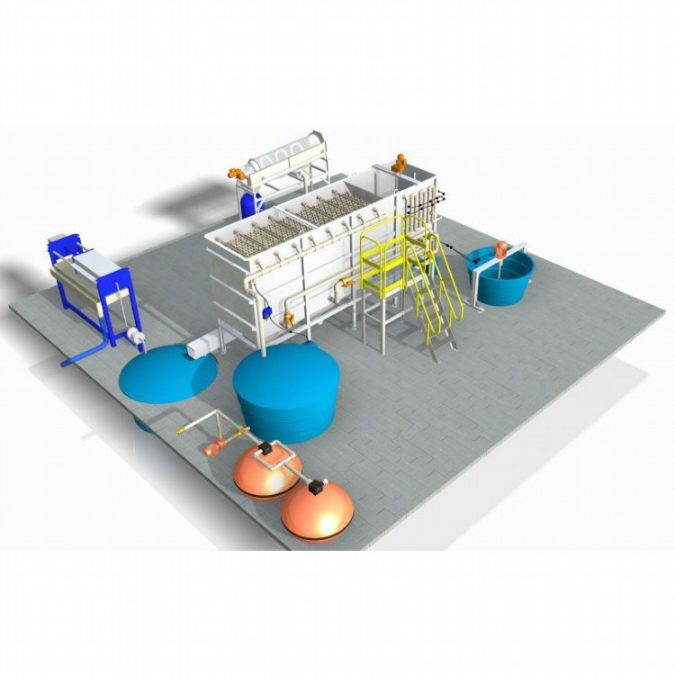

Interplast visitors will have the opportunity to learn a little more about the PE, PP and PET recycling lines and the Seibt industrial effluent treatment station. A 1500Kg/h PET recycling line is capable of recycling approximately 45,000 PET bottles per hour. The Seibt industrial effluent treatment station is a system developed for the treatment, reuse and correct emission of liquid effluent and sludge generated in the plastic recycling process.

Interplast visitors will have the opportunity to learn a little more about the PE, PP and PET recycling lines and the Seibt industrial effluent treatment station. A 1500Kg/h PET recycling line is capable of recycling approximately 45,000 PET bottles per hour. The Seibt industrial effluent treatment station is a system developed for the treatment, reuse and correct emission of liquid effluent and sludge generated in the plastic recycling process.

Mills, crushers, fines separators and binders complete the Seibt solutions. Seibt machines are produced with the highest quality in order to guarantee durability, productivity and robustness to the equipment. They operate in the grinding and recycling of pre- and post-consumer plastic with quality and efficiency.

Seibt machines are known for their robustness and productivity and the company is constantly looking for greater productivity and energy efficiency. The mills have scissor cutting technology, which provides less peak energy during the grinding process. They contribute to reducing production waste, when they act in industrial recycling and act in the recycling of post-consumer plastics.

Seibt – Effluent treatment solutions and accessories for the thermoplastic industry

Located in Nova Petrópolis, Rio Grande do Sul, Seibt supplies machines and equipment for recycling plastics, in pre- and post-consumption processes, serving customers from all over Brazil and Latin America. For 45 years, it has been producing complete recycling systems, in addition to medium and low rotation mills for the reuse of plastic scraps, scraps and scraps in general, designed with the highest technology and according to the customer’s needs.

There are more than 50 models of machines, including mills, agglomerators, shredders, extruders, shredders, exhausters, silos, complete systems for recycling plastics and effluent treatment stations.

Read more