ENGEL do Brasil presents the e-mac 765/180 Fully Electric Injection Machine suitable for Large Molds

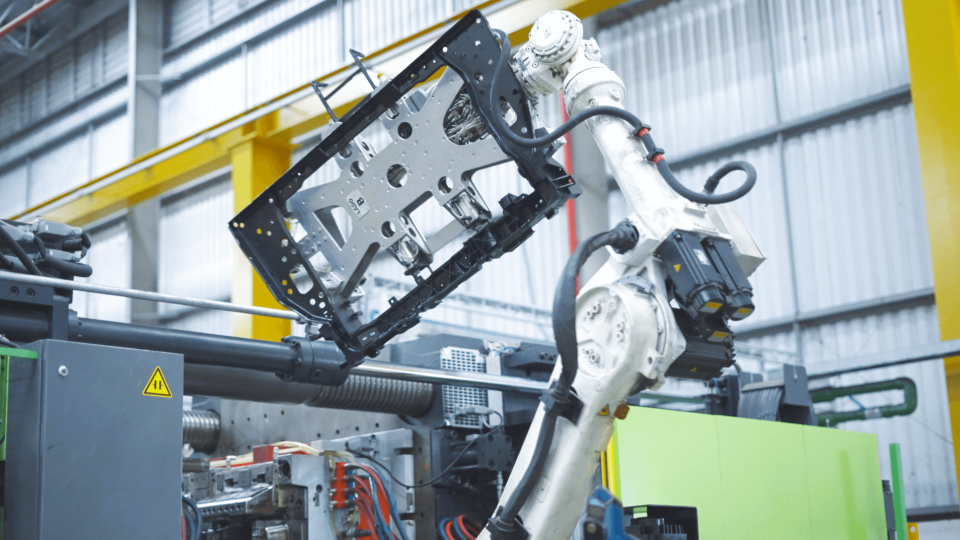

Interplast 2024 has the participation of ENGEL do Brasil, where it presents the most recent version of the fully electric injection machine, the e-mac 765/180. Compact, flexible and efficient, this machine is designed to optimize production space while offering unmatched flexibility and efficiency. The e-mac 765/180 is especially known for its largest column spacing in its class, which facilitates the use of large molds and custom molds.

Furthermore, the encapsulated toggle system requires less lubricant and increases service life, enabling clean and safe production for products in the food and medical technology sectors. ENGEL also has expertise in automation at all levels, from robot integration to peripherals.

The e-mac 765/180 electric injection machine is ideal for a wide range of applications. From producing complex technical components such as small parts with variable and thin wall thicknesses, to manufacturing hospital products that require precision, cleanliness and efficiency, the e-mac 765/180 stands out. Its compact design allows for the creation of compact manufacturing cells, such as those used in the production of pipette tips, and its energy efficiency makes it a sustainable choice for manufacturers concerned about reducing costs and CO2 emissions.

DIFFERENTIALS OF THE ELECTRIC INJECTION MACHINE

The e-mac 765/180 electric injection machine is designed to reduce energy costs by up to 45%, offering significant savings for manufacturers. It adapts individually to the needs of the product, providing personalized injection dynamics. Its design with greater spacing between columns facilitates the use of large molds and customized molds. The e-mac is also ideal for the food and medical technology sectors, thanks to the toggle system being encapsulated, preventing oil leakage at the toggle joints, allowing clean and safe production.

As the only injection molding machine manufacturer with Ecovadis 2023 Sustainability Platinum status, ENGEL is committed to sustainable production. The e-mac 765/180 electric injection machine allows the processing of recycled materials, contributing to the reduction of CO2 emissions. Furthermore, the machine is equipped with thermoregulator control, peripheral integration and intelligent process control, making it an ideal choice for manufacturers seeking innovation and environmental responsibility.

ABOUT ENGEL

ENGEL’s history is marked by pioneering spirit and innovative strength. With nine factories in Europe, North America and Asia, as well as subsidiaries and representatives in more than 85 countries, ENGEL continually works to increase benefits for its customers. ENGEL systems transform raw materials into plastic parts used in various sectors, from the automotive industry to everyday consumer products.

ENGEL not only supplies machines, such as the electric injection model at the fair, but also offers comprehensive services ranging from machine installation and automation, to digital solutions, innovative plastic recycling processes and training. This holistic approach ensures that ENGEL customers can achieve their production objectives in a more sustainable and efficient way until the end of the injection molding machine’s useful life.