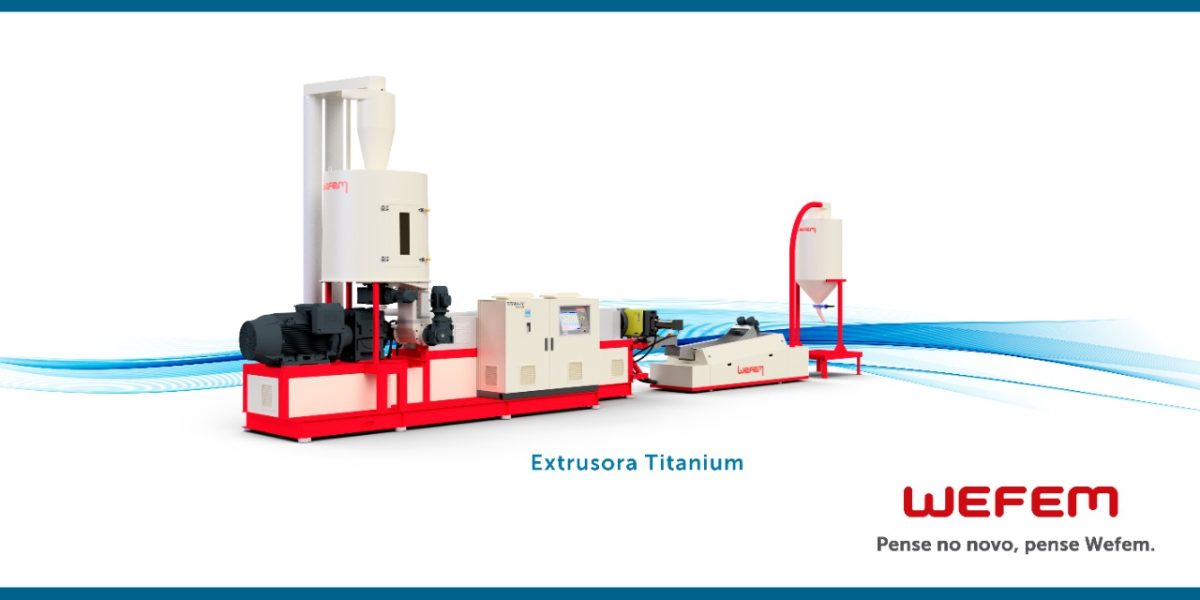

The post-industry or post-consumer plastic film scrap recovery line, starting with grinding and ending with granulation, is Wefem’s highlight at Interplast. The highlight is the 90 mm extrusion line (mill and extruder) with a production capacity of 230 to 300 kg per hour based on polyethylene.

The post-industry or post-consumer plastic film scrap recovery line, starting with grinding and ending with granulation, is Wefem’s highlight at Interplast. The highlight is the 90 mm extrusion line (mill and extruder) with a production capacity of 230 to 300 kg per hour based on polyethylene.

The equipment has the function of extruding flexible or rigid materials, with forced feeding and cutting at the head. The equipment is simple to operate and easy to maintain, but with technologies that help in controlling the process parameters. Companies that use this equipment are focused on the production of polymeric materials that in the process of their manufacture generate losses and need to recover their scraps, in addition to those that work with recycling. The product is already known in the recycling market, but with technological advances in each exhibition.

Specialty in plastic film shavings

Wefem follows the needs of the market, the difficulties of operators and maintenance sectors in the extrusion process. With this, in each detail of the equipment it is possible to see differentials developed for the fluency of the process,

compared to what is on the market. The results are quality granules and time and energy savings.

The fact of developing machines, from compact to large, for the markets for recovery of their own chips or the recycling market, is already a collaboration with the circular economy. THE

Wefem is concerned with developing projects that, in full operation, avoid environmental pollution, such as the specific case of the degassing system in which volatiles are collected in the internal compartments of the extruder and not released into the environment.

About Wefem

Wefem is a young and dynamic company that develops its own projects. It operates in the polymeric scrap recycling market and specializes in meeting the demand for materials in flexible and rigid films.