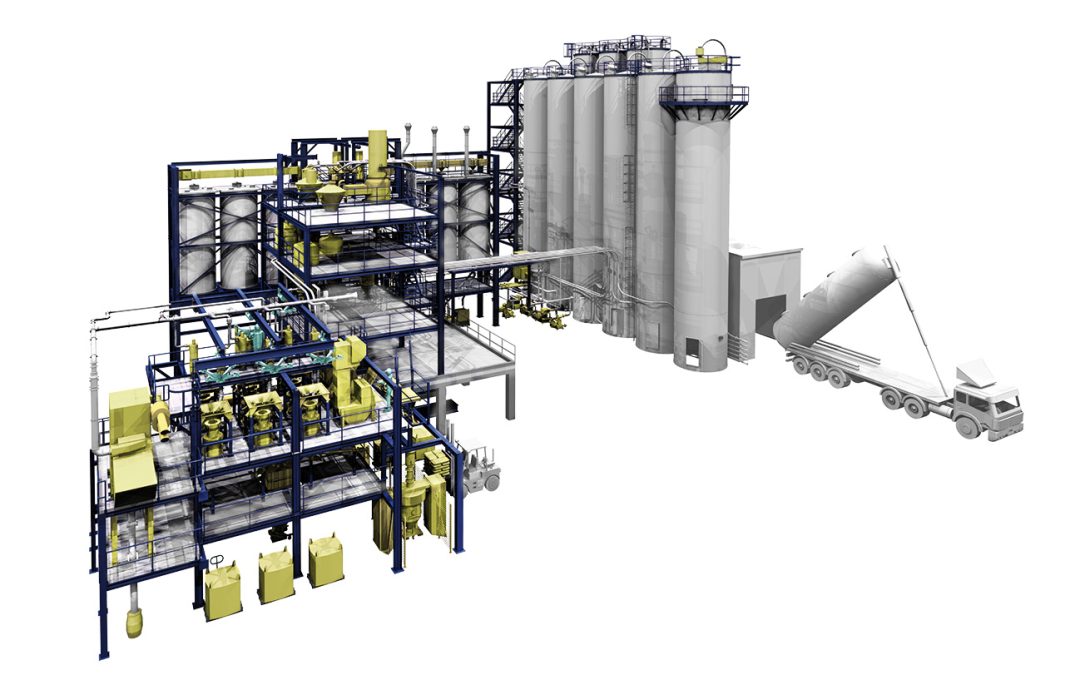

Automation solutions, adhering to the most varied plastic transformation industries and other segments, with a focus on reducing operating costs, will be highlighted by Zeppelin at Interplast. Among the solutions are raw material receiving units (bag unloader, big-bags, trucks, containers), pneumatic transport systems (dense or diluted phase, positive pressure or vacuum), automatic or semi-automatic dosing and weighing systems. for macro/medium/micro ingredients, mixers and coolers and storage or homogenization silos.

Automation solutions, adhering to the most varied plastic transformation industries and other segments, with a focus on reducing operating costs, will be highlighted by Zeppelin at Interplast. Among the solutions are raw material receiving units (bag unloader, big-bags, trucks, containers), pneumatic transport systems (dense or diluted phase, positive pressure or vacuum), automatic or semi-automatic dosing and weighing systems. for macro/medium/micro ingredients, mixers and coolers and storage or homogenization silos.

Automation solutions allow the customer to dedicate himself to the manufacturing activities of his final product, minimizing time spent on handling, storage and preparation of raw materials. Zeppelin uses German technology to manufacture the solutions locally, ensuring the use of cutting-edge technology with access to Finame benefits and prices in local currency.

SPECIALTY IN AUTOMATION SOLUTIONS

The automation solutions provided by Zeppelin are hermetic, that is, the particulate is enclosed without emitting dust into the atmosphere, helping to keep the manufacturing area and the environment clean. Sizing with a qualified engineering team ensures that the system is not oversized, thus avoiding exaggerated spending on Capex (equipment acquisition) and OPEX (operating costs, including energy consumption). The solution makes it possible to use the appropriate resources for each process.

ABOUT ZEPPELIN

Zeppelin is a century-old German multinational company with a branch in Brazil, with 45 years of experience in the national market. Locally manufactures valves, filters, screws, hoppers, carousel, among other automation solutions. In addition to the plastics segment (2nd and 3rd generations of the chain), it operates in the areas of food, rubber, cement, steel, chemicals, fertilizers, among other markets.